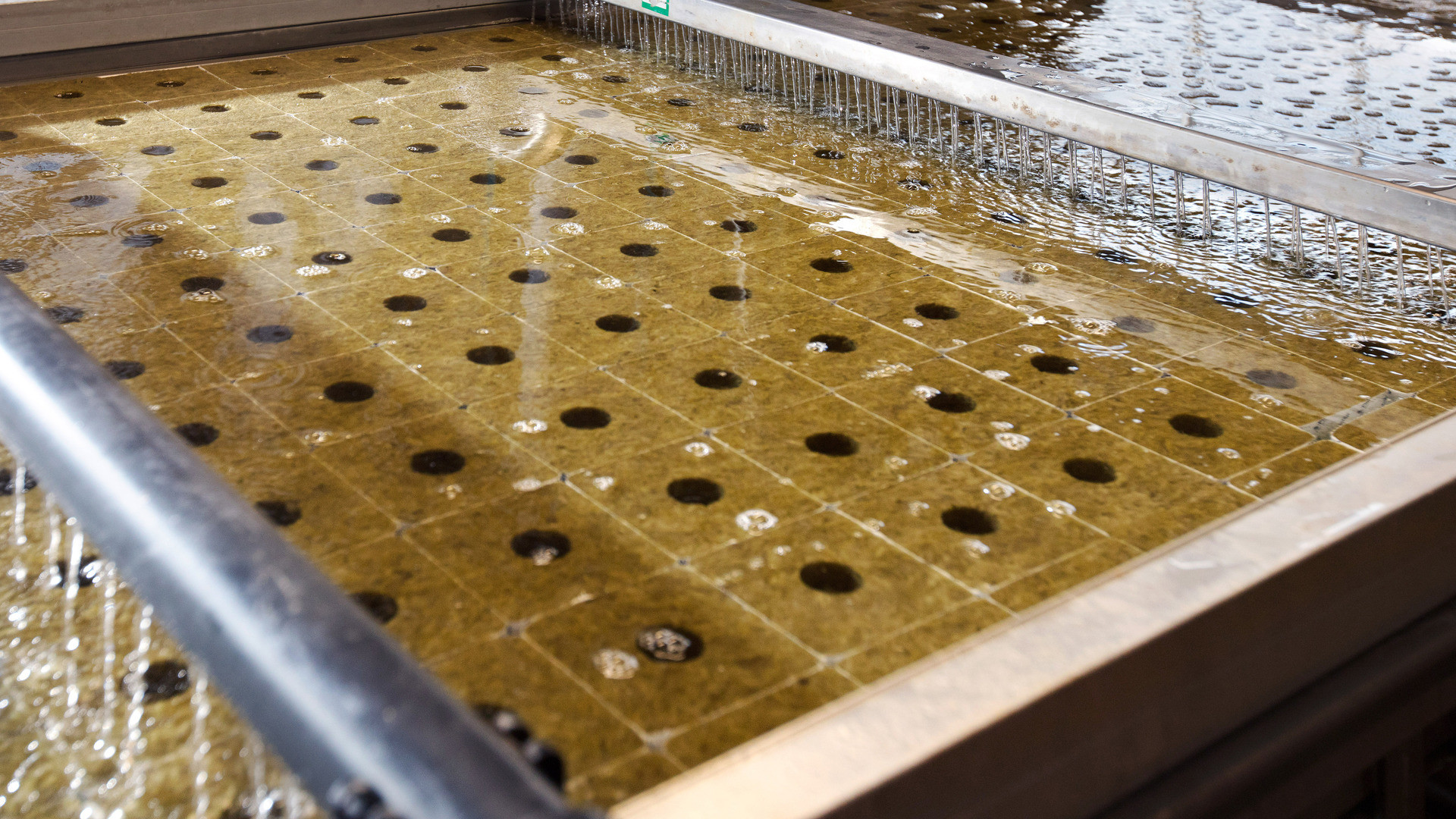

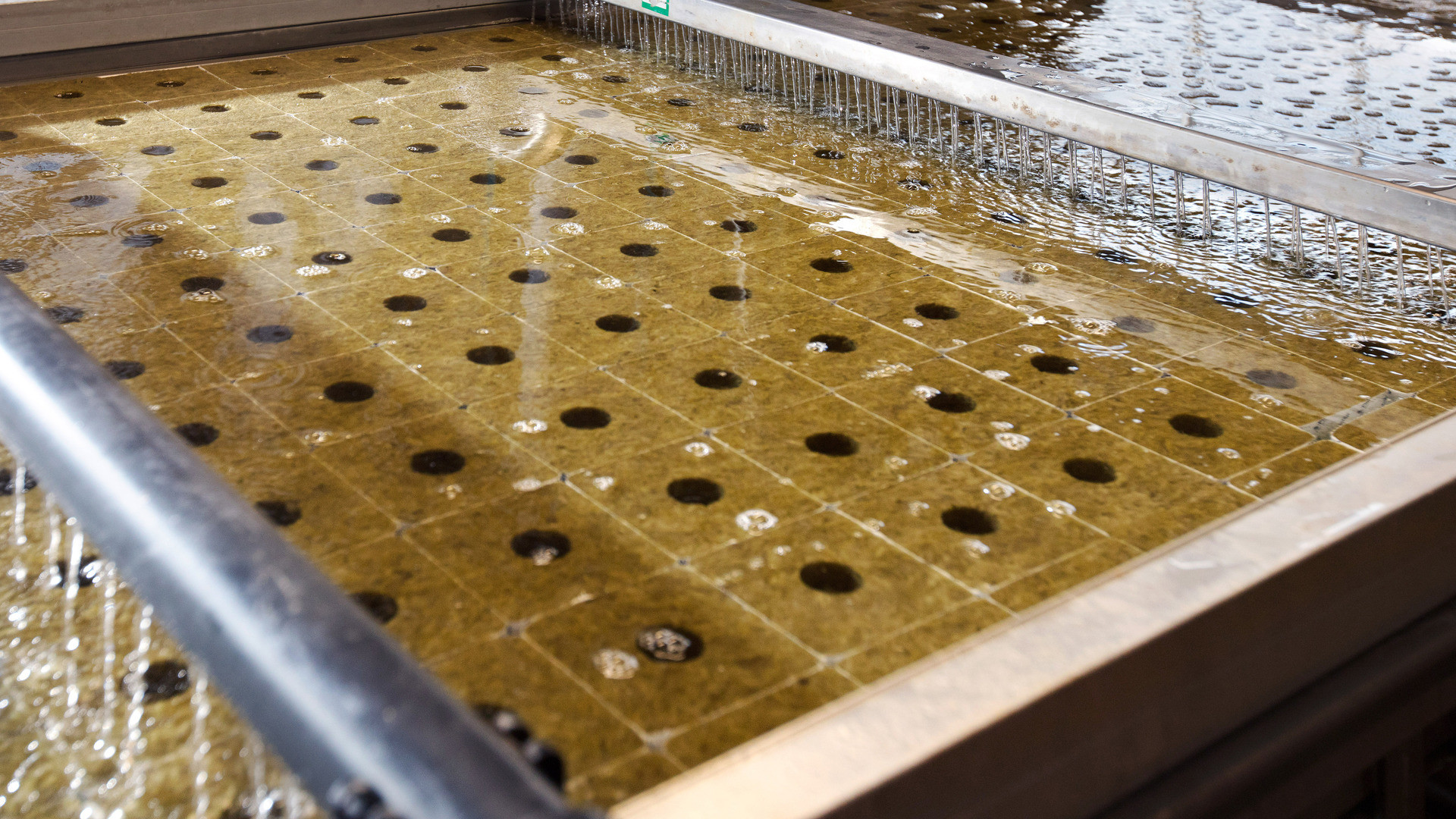

It is ideal to use an ‘open’ belt under the spray bars. This allows excess water to drain well into the drain pan under the belt, reducing the chances of air trapping in the block.

The speed of the conveyor belt also plays a role here. Try to maintain a speed of 2-3 cm/sec. Too high a speed will cause the blocks to run under the spray bars too quickly, giving them too little time to properly absorb the moisture after each spray bar.

Furthermore, the water temperature should be above 18 degrees, optimum is around 21 degrees. If the water temperature is low, the fibres do not absorb the moisture as well.

If necessary, check the amount of water supplied using a ‘Grodan water volume bucket’. The rule of thumb is that this should be between 1.8 and 2.5 times the volume of a block.

It is important to weigh the weight of the blocks structurally and randomly after initial wetting. This should then also be noted on the freshening list. If blocks weigh less than the lower limit, this is a signal that the blocks have not been thoroughly wet. It is important to take action on this right away. Is the water offered irregularly? Is the water pressure sufficient and constant? If the blocks have not been wet properly, this leads directly to growth retardation and heterogeneity, so it is important to check and ensure this process regularly.

The minimum weights required after initial wetting of the most common block types:

| Block Type (LxBxH) | Block Volume | Min. Weight after initial saturation (grams) |

| 100*100*65 | 650 CC | 553 |

| 100*100*75 | 750 CC | 638 |

| 100*100*85 | 850 CC | 723 |

| 150*100*65 | 975 CC | 829 |

| 150*100*75 | 1125 CC | 956 |

| 150*100*85 | 1275 CC | 1084 |

| 200*100*65 | 1300 CC | 1105 |

| 200*100*75 | 1500 CC | 1275 |

Key points:

- Repetitive application of water through spray bars (5 bars) to saturate the rockwool blocks

- Sufficient distance between the beams (50 cm) so that the water has time to sink through the blocks

- Conveyor under the spray beams must be permeable so that the water can pass through the blocks, preventing air inclusion

- Velocity of the conveyor belt should not be too high so that sufficient water is offered and the blocks can properly absorb the moisture

- Temperature of the water should not be too low.

- Regularly scheduled checking and writing down weights is an important requirement to ensure the wetting process.